In order to ensure that new products are designed with stable quality and without bad surprises our team uses checklists that include the below check points for each milestone in the development process.

CONTROL POINT

Kick off

- Project evaluation report

- DFMEA Report

- Technology Risk (TR) Assessment

- Key component risk tracking and documentation

- Benchmarking device evaluation

- Benchmarking device evaluation

- Quality standard evaluation

EVT

- PCB Review Report

- PCB stacking/MD Review report

- Mold Review report

- SW/HW/Reliability/CT Test plan

- Key performance pre-test: such as drop test

- EVT assembly report

- TR tracking assessment

- Production fixture evaluation report

DVT1

- DVT1 trail production report

- EVT Review / transfer report

- HW testing and risk tracking

- Reliability test / Risk point tracking

- Single material acceptance test

- Final list of production fixtures

- Supplier (SQE) key material trial production/CPK report

- TR tracking assessment

- SOP and WI conference sharing

DVT2

- DVT1 Review / transfer report

- SOP/Production fixture import

- HW Testing and Risk tracking

- Reliability test /Risk point tracking

- SW test and Score card Maturity

- TR tracking assessment

- DVT2 trail production report

PVT

- DVT2 Review / transfer report

- HW/MD/Improved device acceptance and tracking

- Reliability test acceptance and tracking

- SW and Performance Maturity Acceptance

- Material approval seal

- EWP analysis report

- TR tracking assessment

- PVT Trial production summary report

PP/MP

- PVT Review / Transfer report

- ORT test

- SOP/SIP final release

- PFMEA report out-put

- Gold sample comnfirmation

- Project summary and feasibility report for mass production

- Production daily/monthly report, maintenance daily report

- EWP analysis report

- Simulate FAI detection

- TR tracking assessment

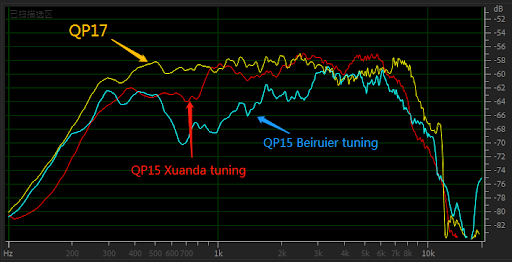

Our experts in different engineering aspects such as, acoustics, LED lighting, mechanical structure design will validate ODM designs and support to achieve the required performance